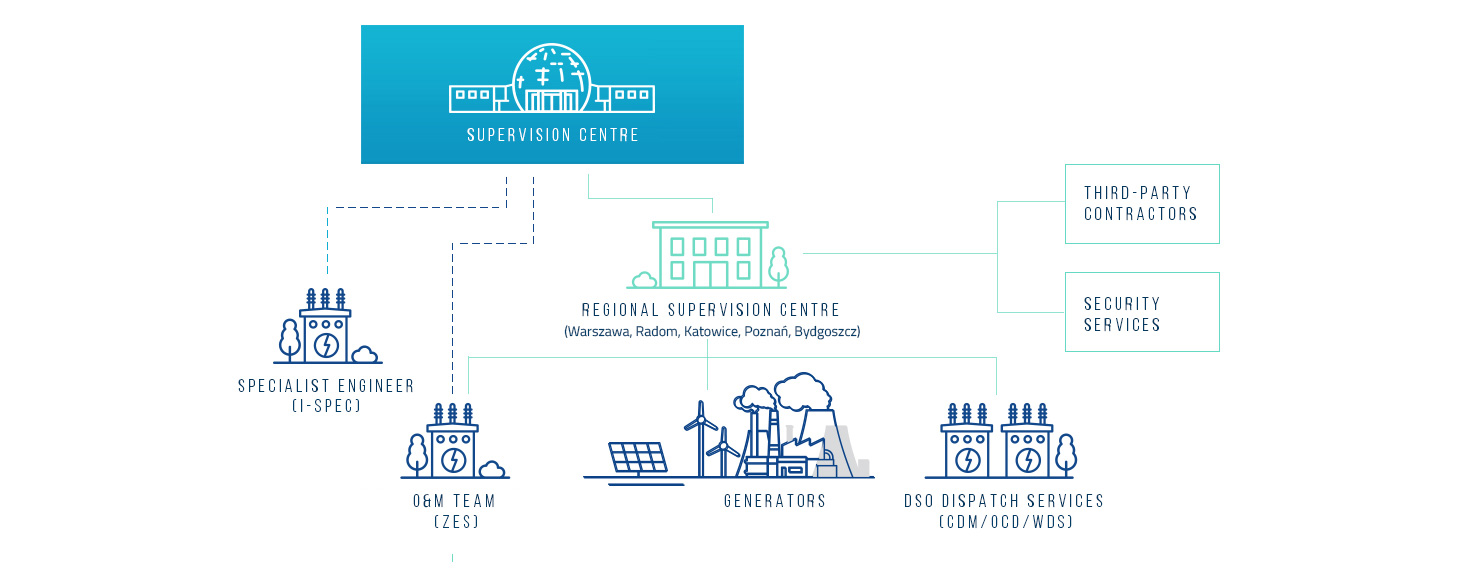

The CN/RCN operation supervision services play a key role in the event faults or failures occur in transmission network assets during which actions are initiated and fault elimination processes are activated on the basis of signals from SCADA systems or notifications from other entities. The services monitor the condition of transmission network equipment on an ongoing basis, defining time or quantitative constraints in their operation, affecting the operational management conditions.

Actions taken by CN/RCN services in the event of failure include:

- the analysis of causes, origin and extent of disturbance,

- organisation of incident site protection,

- taking the decision on the method of disturbance elimination,

- dispatching available resources of O&M Teams (ZES) and Specialist Engineers (I-SPEC) in order to organise the elimination of disturbance,

- supervising and coordinating disturbance elimination work.

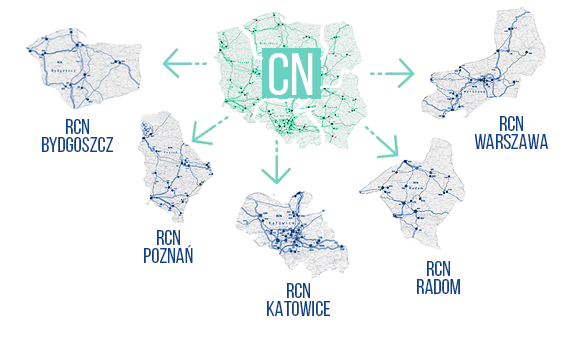

In the event an extensive cross-zonal failure occurs (between responsibility areas of territorially competent RCNs), the individual RCNs cooperate with one another. In such a case, the Supervision Centre coordinates all activities of PSE’s operation services from different areas and subcontractors commissioned by PSE.

In the interest of ensuring operational continuity, the CN/RCN operation supervision services are prepared to provide for a potential crisis situation that necessitates leaving the regular workplace, without losing the ability to perform basic tasks, primarily to exercise continuous supervision over the operation and condition of network assets. In 2018, the process of commissioning backup CN/RCN locations was completed. Since 1 January 2019, the centres have been providing full functional redundancy for the primary centres, owing to which they significantly improve the operational continuity of CN/RCN operation supervision services.

In the network assets maintenance process, the CN/RCN operation supervision services supported by O&M Teams (ZES) and Specialist Engineers (I-SPEC), who have the requisite knowledge and skills for direct work on equipment. There are 28 PSE O&M Teams established across the country. Through their work, ZES employees ensure the security of operating as well as diagnostic and maintenance activities. The competence and specialised skills of ZES employees are maintained at a high level owing to systematic technological training. Besides, owing to the maintenance personnel development programme launched, the training provided is comprehensive and systematic.